Cerused Finishing collection

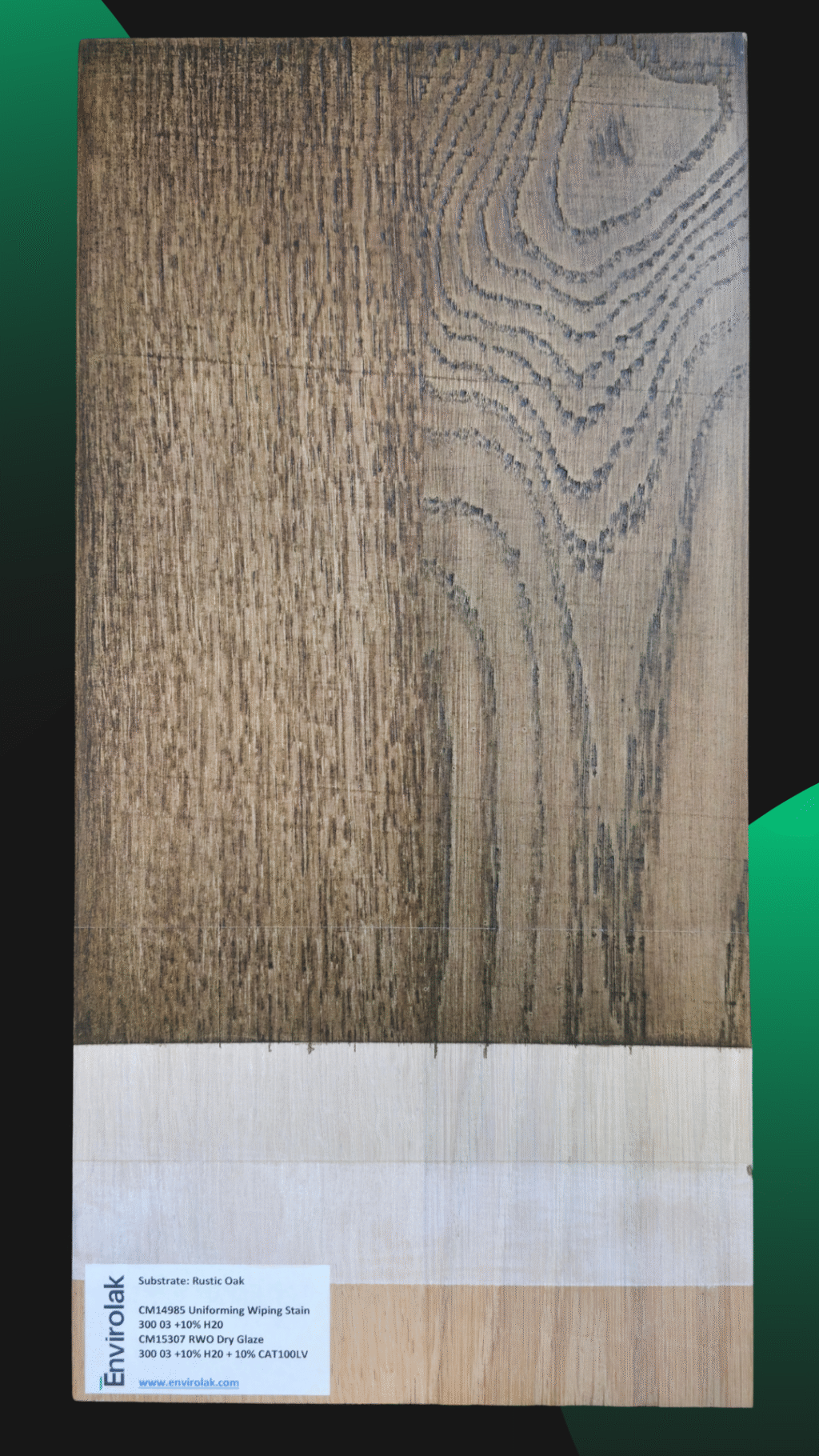

Cerused Finishing System #1

300 Series 3 Sheen

🪵 Refined & Repeatable – A Finish You Can Trust 🎨

At our training center, we’re all about hands-on testing to help customers build solid, repeatable SOPs. Here’s a recent panel that highlights a balanced, low-sheen finish with subtle glaze accents:

Process Breakdown:

1️⃣ Sand raw wood with 180 grit

2️⃣ Apply CM14985 Uniformining wiping stain

3️⃣ Seal with 300 03 + 10% water (1K)

4️⃣ Apply CM15307 RWO dry glaze

5️⃣ Sand back with 400 grit + maroon non-woven pad

6️⃣ Final coat: 300 03 + 10% CAT100LV + 10% water (2K)

The outcome? A controlled, consistent look with great clarity and just the right amount of glaze hold—ideal for clean, professional finishes in production settings.

💡 These panels aren’t just for show—they’re tools our specialists use every day to guide customers with confidence.

Cerused Finishing System #2

100 Series 5 Sheen

🛠️ Finishing Focus – Uniformity Meets Depth 🎨

Another standout panel from our training center! This finish is all about achieving a clean, uniform tone with subtle glaze definition—perfect for customers aiming for consistency with character.

Here’s the step-by-step process:

1️⃣ Sand raw wood with 180 grit

2️⃣ Apply CM14985 Uniformining wiping stain

3️⃣ Seal with 100 05 + 10% water (1K)

4️⃣ Apply CM15307 RWO dry glaze

5️⃣ Sand glaze back with 400 grit + maroon non-woven pad

6️⃣ Finish with 100 05 + 10% water (1K)

The final look? Smooth, even color with just the right amount of glaze highlight—ideal for production environments where repeatability is key.

We test these finishes in-house so our team can confidently support customers in developing reliable, efficient SOPs. 💡

Cerused Finishing System #3

900 Series Zero Sheen

🪵 Matte Mastery – Low Sheen, High Impact 🌫️

Check out this panel from our training center, finished with a zero sheen clear coat for a smooth, natural look that still shows depth and character.

Step-by-step process:

1️⃣ Sand raw wood with 180 grit

2️⃣ Apply CM14985 Uniformining wiping stain

3️⃣ Seal with 900 00 + 10% CAT100LV (2K)

4️⃣ Apply CM15307 RWO dry glaze

5️⃣ Sand glaze back with 400 grit + maroon non-woven pad

6️⃣ Topcoat with 900 00 + 10% CAT100LV (2K)

The result? A beautifully muted, ultra-matte finish that still highlights the wood’s natural grain and subtle glaze detail—ideal for modern, minimalist aesthetics.

These in-house test panels help our team guide customers with real product insight when developing standard operating procedures. 👨🏭👩🏭

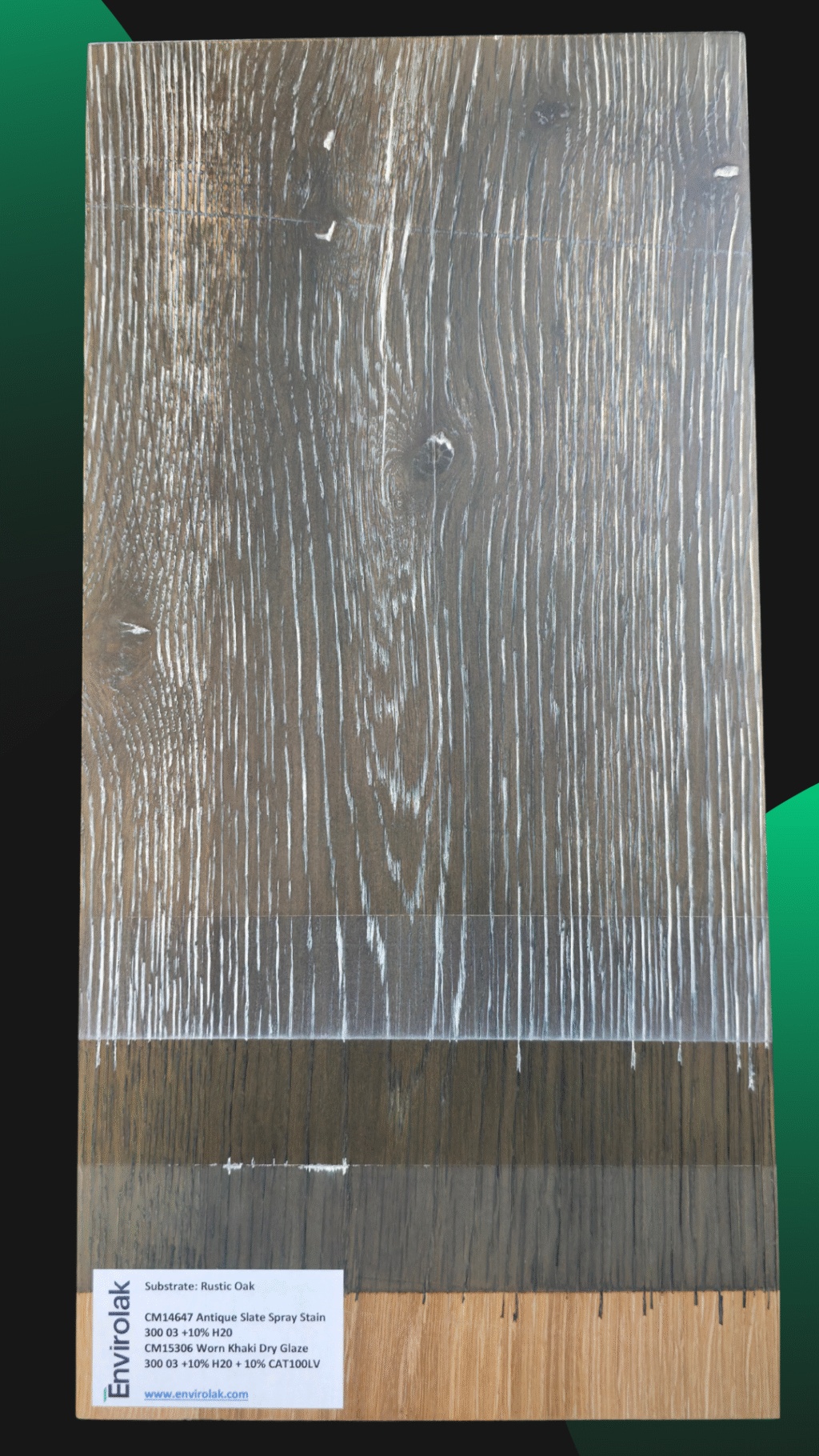

Cerused Finishing System #4

300 Series 3 Sheen

🎯 Depth, Contrast & Control – The Perfect Glaze Combo 🎯

Here’s another standout finish straight from our training center, where our specialists explore how stains, sealers, and glazes interact to achieve consistent, high-quality results. On rustic oak.

Step-by-step process:

1️⃣ Sand raw wood with 180 grit

2️⃣ Apply CM14647 Antique Slate spray stain

3️⃣ Seal with 300 03 Clear + 10% water (1K)

4️⃣ Apply CM15306 Worn Khaki dry glaze

5️⃣ Sand glaze back with 400 grit + maroon non-woven pad

6️⃣ Topcoat with 300 03 Clear + 10% CAT100LV & 10% water (2K)

The final look delivers rich contrast and subtle layering, showing just how much impact the right glaze and base combo can make. 💡

These controlled tests help our team support customers in building dependable SOPs with real-world product insight.

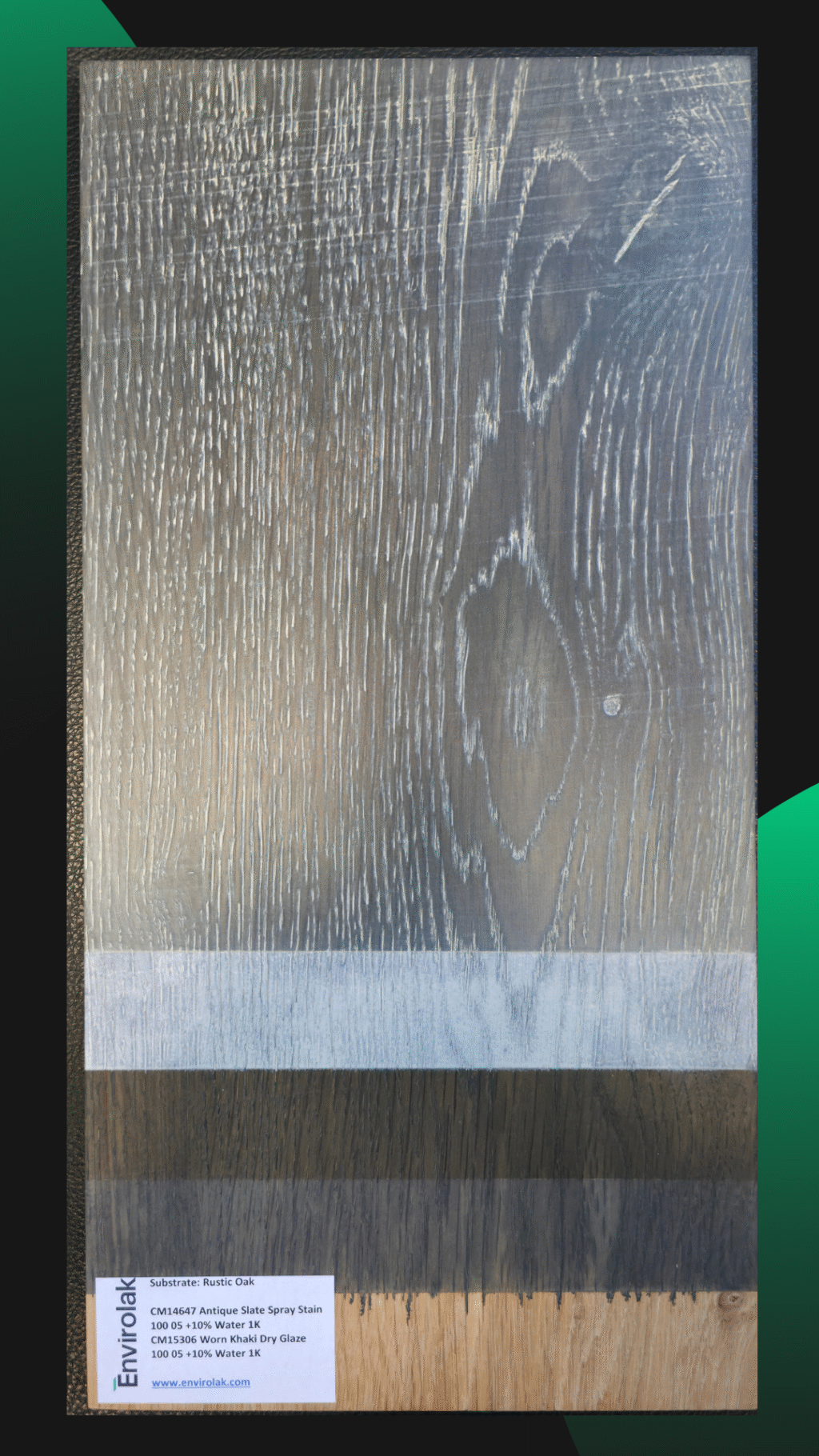

Cerused Finishing System #5

100 Series 5 Sheen

🌫️ Warm Tones with Character – A Subtle, Layered Finish 🌫️

Another panel from our training center, where we explore how base tones and glazes interact to shape the final look. This process features warm undertones and gentle contrast—perfect for projects where subtlety speaks volumes. On rustic oak.

Here’s the breakdown:

1️⃣ Sand raw wood with 180 grit

2️⃣ Apply CM14647 Antique Slate spray stain

3️⃣ Seal with 100 05 Warm Clear + 10% water (1K)

4️⃣ Apply CM15306 Worn Khaki dry glaze

5️⃣ Sand glaze back with 400 grit + maroon non-woven pad

6️⃣ Topcoat with 100 05 Warm Clear + 10% CAT100LV & 10% water (2K)

The result? A warm, refined finish with soft glaze retention and just the right amount of clarity. Great for developing consistent, repeatable SOPs in the field.

🔍 These hands-on tests are how we ensure our team—and our customers—stay ahead with finish quality and application knowledge.

Cerused Finishing System #6

300 Series 3 Sheen

✨ Mastering the Finish: Antique Slate with Worn Khaki Glaze ✨

Check out this detailed process from our training center, showcasing the perfect balance between base stain, glaze, and clear coats to achieve a stunning, textured finish. On rustic hickory.

Step-by-step:

1️⃣ Sand raw wood with 180 grit

2️⃣ Apply CM14647 Antique Slate spray stain

3️⃣ Seal with 300 03 Clear + 10% water (1K)

4️⃣ Apply CM15306 Worn Khaki dry glaze

5️⃣ Sand glaze off with 400 grit + maroon non-woven pad

6️⃣ Topcoat with 300 03 Clear + 10% CAT100LV & 10% water (2K)

This technique highlights how the glaze bites into the base coat, adding depth and character while the clear coats protect and enhance the look.

Perfect insights for developing reliable SOPs and helping customers nail their finishes every time! 👌

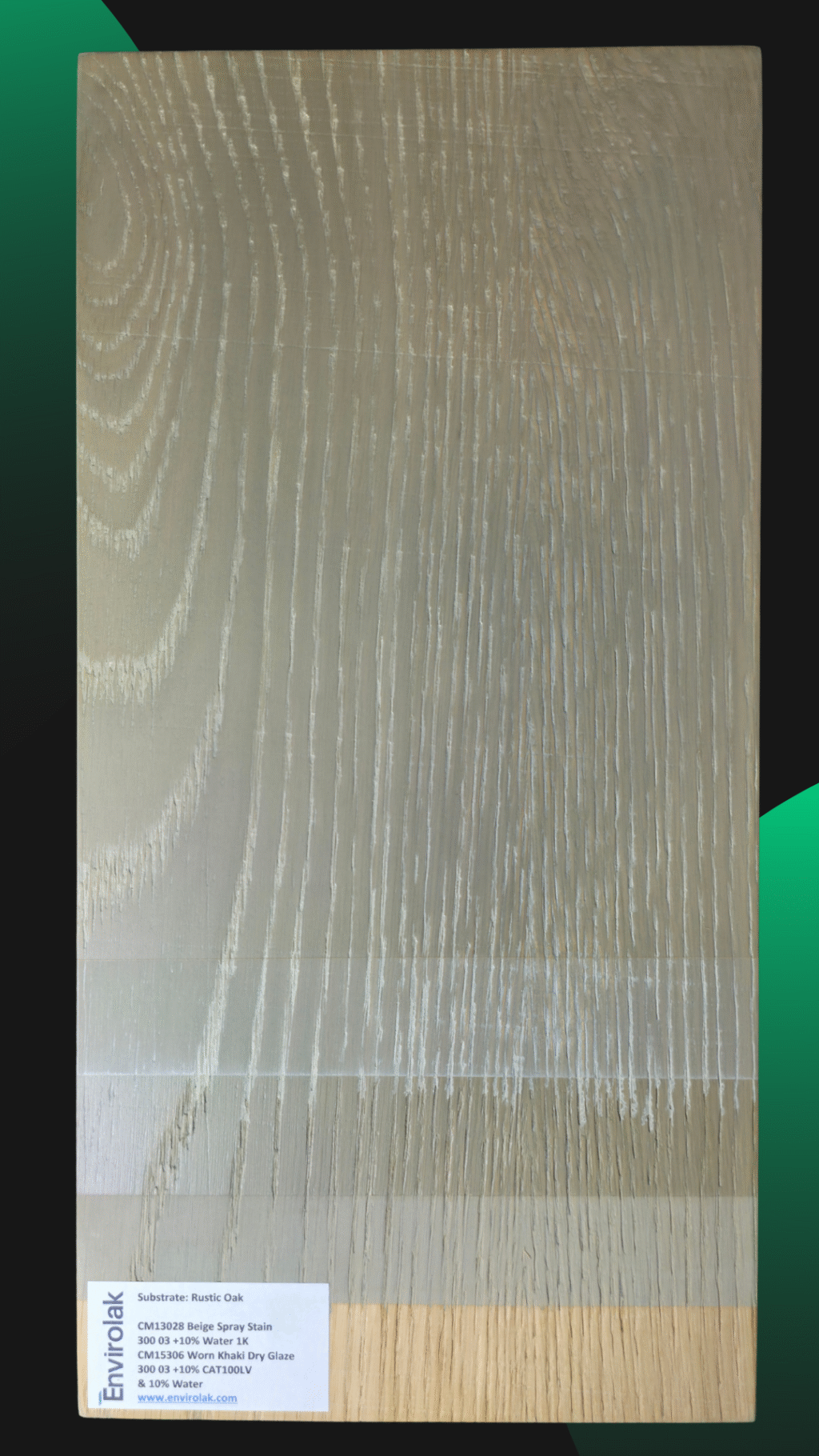

Cerused Finishing System #7

300 Series 3 Sheen

🪵✨ From Raw Wood to Refined Finish ✨🪵

Here’s a look at one of our signature multi-step finishes that brings out depth, warmth, and character in every piece. On rustic oak.

1️⃣ Sanded smooth with 180 grit

2️⃣ Sprayed with CM13028 Beige stain for a soft, natural base

3️⃣ Sealed with 1K 300 03 + 10% water

4️⃣ Layered with CM15306 Worn Khaki dry glaze for that aged, vintage look

5️⃣ Glaze softened by sanding off with 400 grit + maroon non-woven pad

6️⃣ Protected with a 2K topcoat (300 03 + CAT100LV + 10% water) for durability

👀 The result? A timeless, hand-finished look that’s built to last.

📐 Perfect for custom cabinetry, furniture, and feature walls.

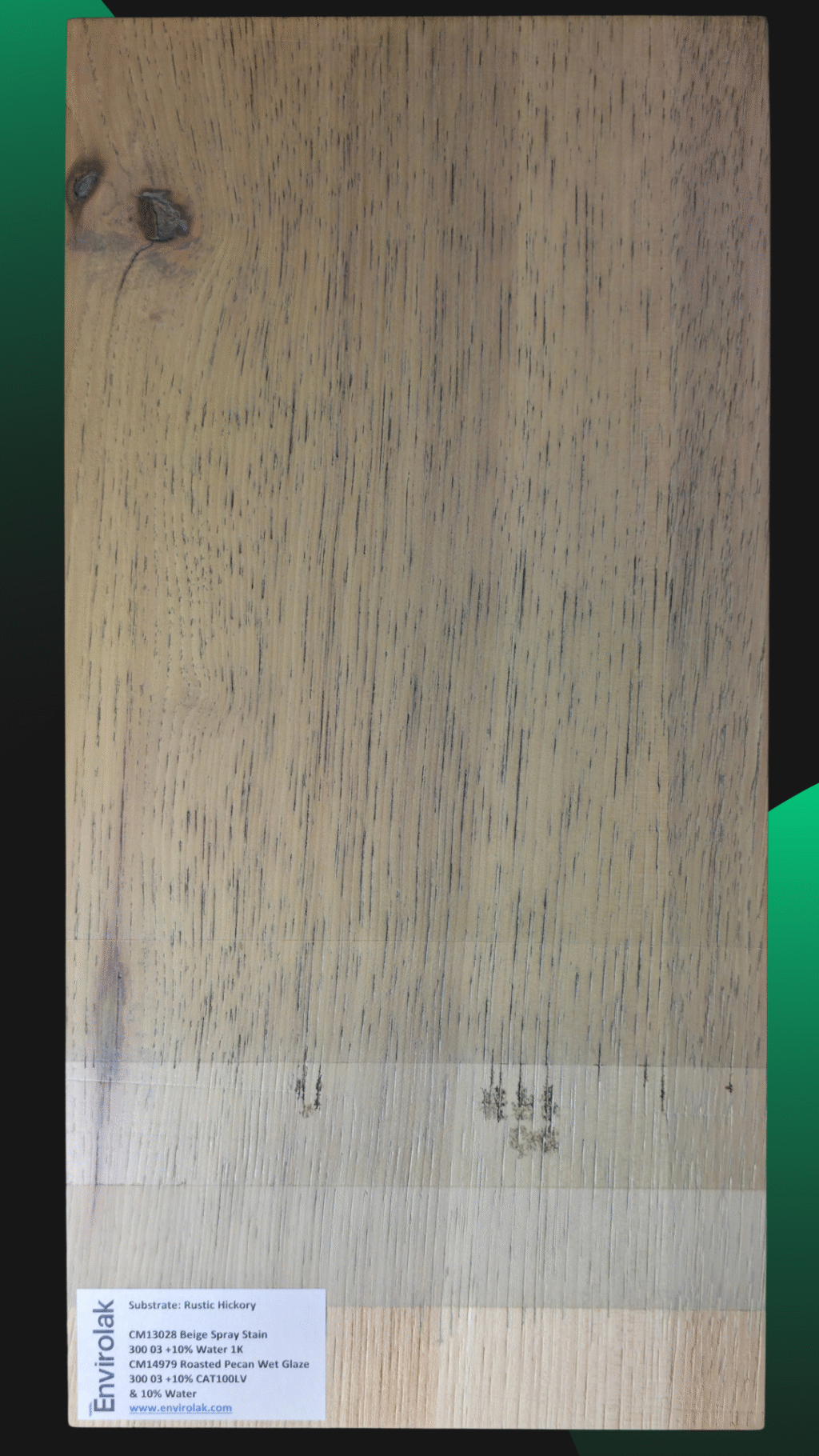

Cerused Finishing System #8

300 Series 3 Sheen

🪵🔥 Warm. Rich. Refined. 🔥🪵

Here’s a behind-the-scenes look at one of our favorite wood finishing processes using our signature Roasted Pecan wet glaze. On rustic hickory.

1️⃣ Sanded smooth with 180 grit

2️⃣ Sprayed with CM13028 Beige Stain for a soft, even base

3️⃣ Sealed with 1K 300 03 + 10% water

4️⃣ Glazed with CM14979 Roasted Pecan — hand-wiped for depth and detail

5️⃣ Protected with a 2K topcoat (300 03 + 10% CAT100LV + 10% water) for durability and a flawless finish

This finish adds warmth, subtle contrast, and a handcrafted look that stands out in any space.

📸 Custom cabinetry, furniture, or feature pieces — we bring the character to the surface.

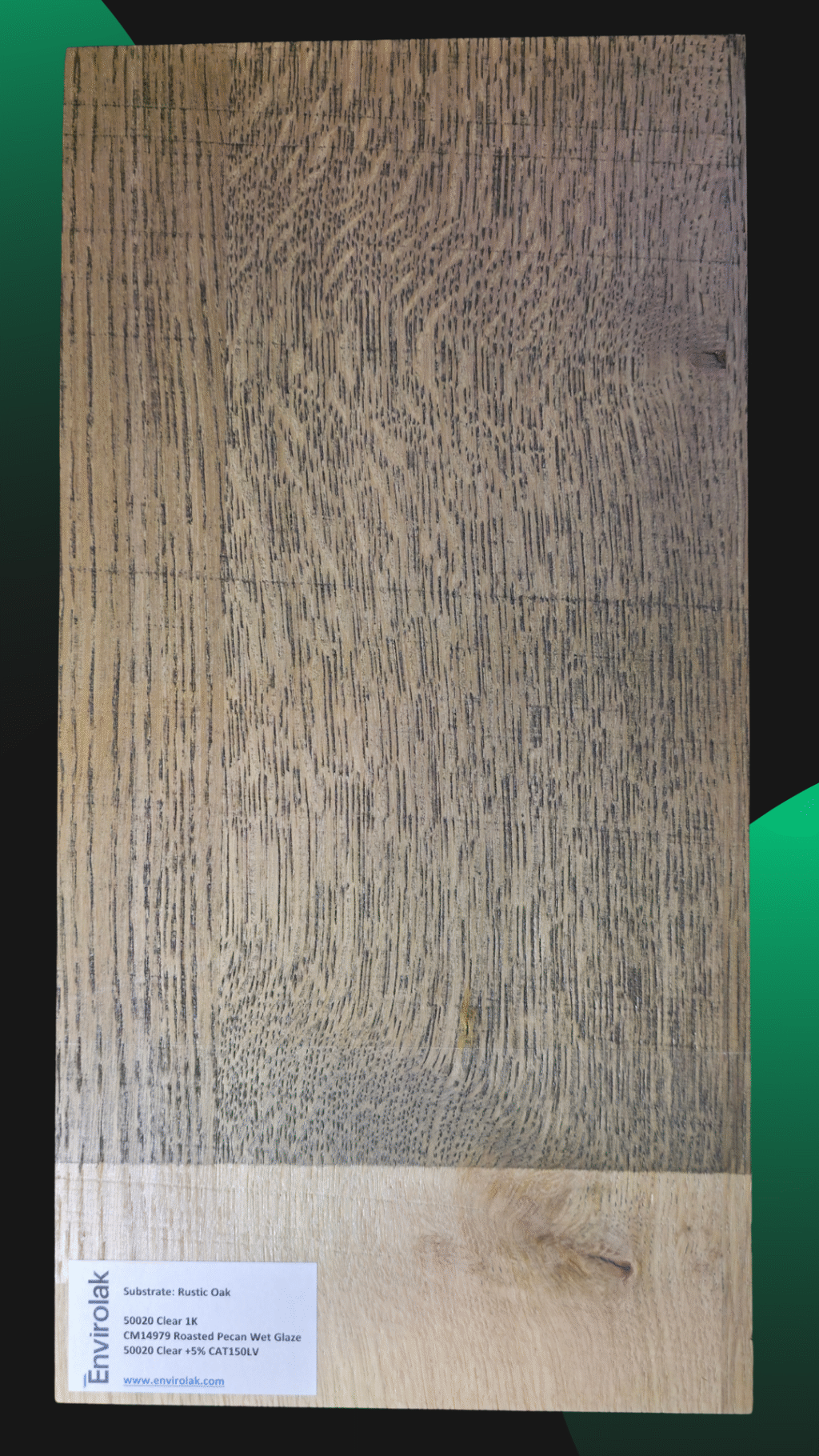

Cerused Finishing System #9

500 Series 20 Sheen

🪚✨ Simple Process. Stunning Results. ✨🪚

Here’s how we create a clean, classic finish with warm undertones using our Roasted Pecan glaze

on rustic oak:

1️⃣ Sanded raw wood with 180 grit

2️⃣ Sealed with 1K Clear Coat (500 20)

3️⃣ Applied CM14979 Roasted Pecan Wet Glaze

4️⃣ Hand-wiped for perfect tone and texture

5️⃣ Finished with a durable 2K topcoat (500 20 + 5% CAT100LV)

🔍 This finish highlights the natural grain while adding depth and warmth — ideal for high-end cabinetry, furniture, or feature pieces.

📐 Less steps. More character.

Cerused Finishing System #10

500 Series 20 Sheen

🪚✨ Simple Process. Stunning Results. ✨🪚

Here’s how we create a clean, classic finish with warm undertones using our Roasted Pecan glaze

on rustic hickory:

1️⃣ Sanded raw wood with 180 grit

2️⃣ Sealed with 1K Clear Coat (500 20)

3️⃣ Applied CM14979 Roasted Pecan Wet Glaze

4️⃣ Hand-wiped for perfect tone and texture

5️⃣ Finished with a durable 2K topcoat (500 20 + 5% CAT100LV)

🔍 This finish highlights the natural grain while adding depth and warmth — ideal for high-end cabinetry, furniture, or feature pieces.

📐 Less steps. More character.

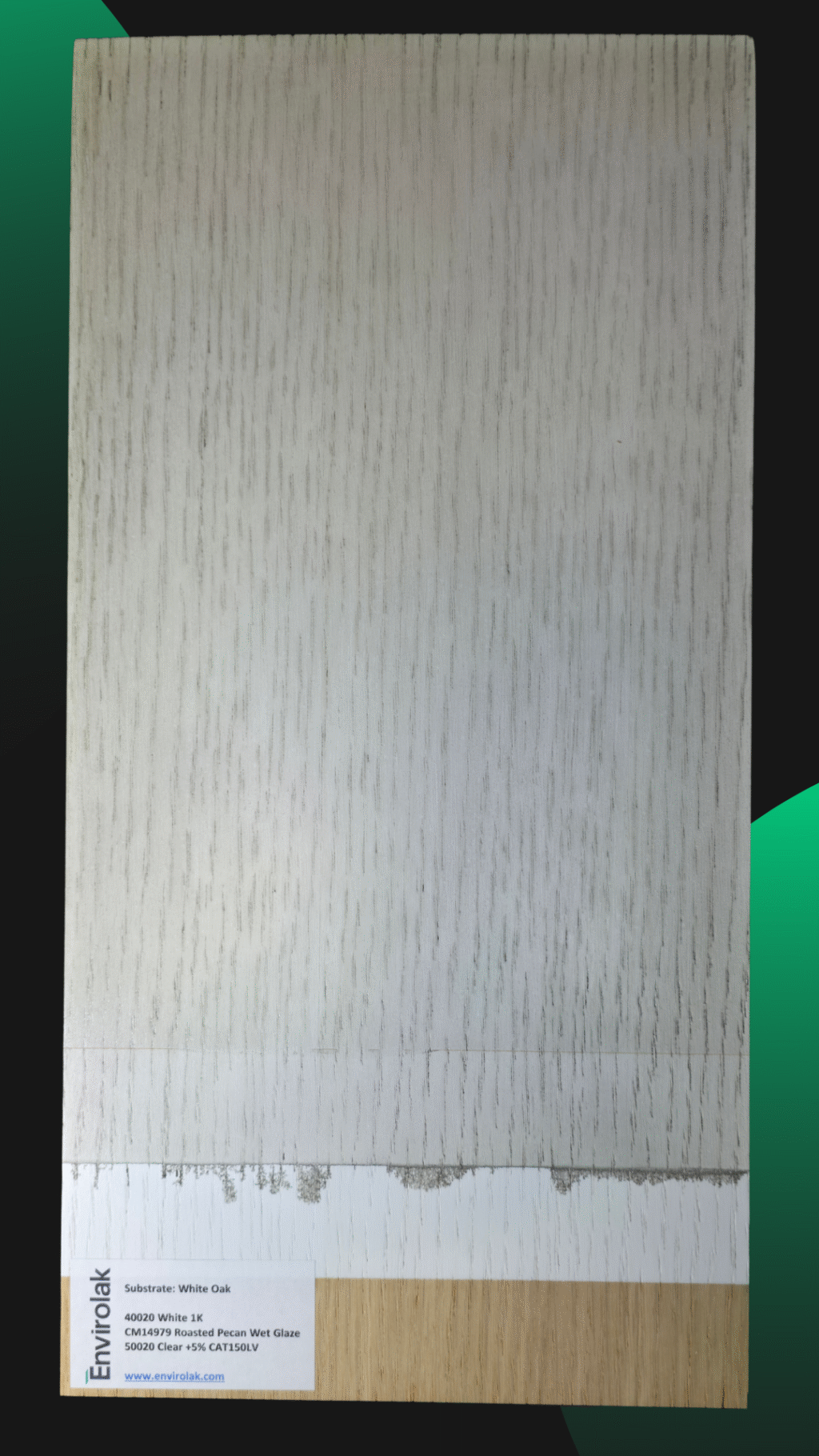

Cerused Finishing System #11

400 Series 20 Sheen

🎨🪵 Layered Contrast. Timeless Style. 🪵🎨

This finish brings out the beauty of the grain while adding soft warmth and subtle contrast — here’s how we do it on white oak:

1️⃣ Sanded raw wood with 180 grit

2️⃣ Sprayed with 400 20 White (1K basecoat)

3️⃣ Applied CM14979 Roasted Pecan Wet Glaze

4️⃣ Hand-wiped with a cotton rag for natural aging effect

5️⃣ Sealed with a 2K clear coat (500 20 + 5% CAT100LV) for durability and clarity

🤍+🤎 The result? A soft white base with warm pecan undertones — perfect for cabinetry, furniture, and custom interiors that need a touch of elegance with character.

Cerused Finishing System #12

300 Series – 3 Sheen

🌰✨ Depth. Warmth. Harmony. ✨🌰

This finish blends natural tones and hand-applied character for a rich, timeless look. Here’s how we create it on rustic oak:

1️⃣ Sanded raw wood with 180 grit

2️⃣ Applied CM14787 Harmonizing Wiping Stain for a balanced, even tone

3️⃣ Sealed with 1K 300 03 + 10% water

4️⃣ Applied CM14979 Roasted Pecan Wet Glaze

5️⃣ Hand-wiped with a cotton rag to reveal subtle depth and grain detail

6️⃣ Finished with a durable 2K topcoat (300 03 sheen + 10% CAT100LV + 10% water)

🪵 This process enhances the natural wood while adding soft warmth and a handcrafted feel — perfect for custom cabinetry, furniture, and statement pieces.

Cerused Finishing System #13

300 Series – 3 Sheen

🤎✨ Natural Warmth. Expertly Layered. ✨🤎

Here’s how we create a beautifully balanced, warm wood finish using spray stain, glaze, and a durable clear topcoat on rustic oak:

1️⃣ Sanded raw wood with 180 grit

2️⃣ Sprayed with CM13028 Beige Stain for a soft, neutral base

3️⃣ Sealed with 1K 300 03 + 10% water

4️⃣ Applied CM14979 Roasted Pecan Wet Glaze for rich warmth and contrast

5️⃣ Hand-wiped with a cotton rag to enhance grain definition

6️⃣ Finished with a smooth 2K topcoat (300 03 sheen + 10% CAT100LV + 10% water)

🔥 The result? A refined, layered finish that’s both timeless and durable — perfect for high-end cabinetry and custom woodwork.